Depressuring Basic

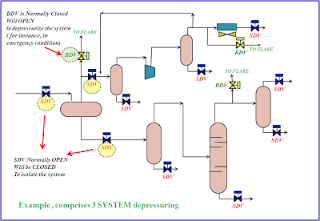

- In case of fire, the operator will push the EDP push button in

the control room. That will initiate SDV valves closing at both outlet and

inlet of an equipment and BDV valves opening. The hydrocarbon fluid will be

released to flare so that the pressure of the system will be depressurized to

lower pressure at certain. (The pic is stolen from another blog, its too good not to steal..the link to that blog is http://process-eng.blogspot.ca/2012/05/basic-depressuring-why-15-minutes.html)

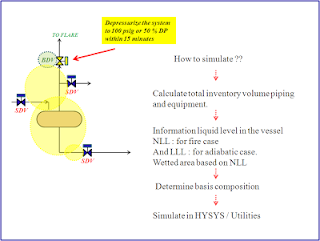

- For thickness of vessel less than 1 inch, the system is

depressurized to 100 psig, and for more than 1 inch thickness can be

depressurized to 50% of design pressure. The depressuring time can be longer

and less than 15 minutes. The depressuring time of 15 minutes is only an example

in API STD 521 which is applicable for carbon steel vessel with has thickness

greater than 1 inch.

- Depressuring time depends on the vessel thickness

- Refer to section 5.15.1.2 in API 521 for graphs for steel plates

and carbon steel for various thicknesses 3.2 mm, 12.7 mm and 25.4 mm thickness.

- Adiatbatic depressuring case

- Normally for most plants are shutdown for annual maintenance

purpose. Such a system is depressurized to atmosphere condition. In this case,

the system is depressurized in adiabatic condition, which means no heat input

to the system. During depressurization, the pressure decreases, and the

temperature decreases as well. The final temperature of adiabatic depressuring

could be very low. As Process Engineer, we have responsibility to determine the

Minimum Metal Design Temperature (MDMT) for each system zone based on this

case.

- Fire case is use only for define max capacity of BDV and flare

system.

- In Hysys we can calculate depressurization by:

No comments:

Post a Comment